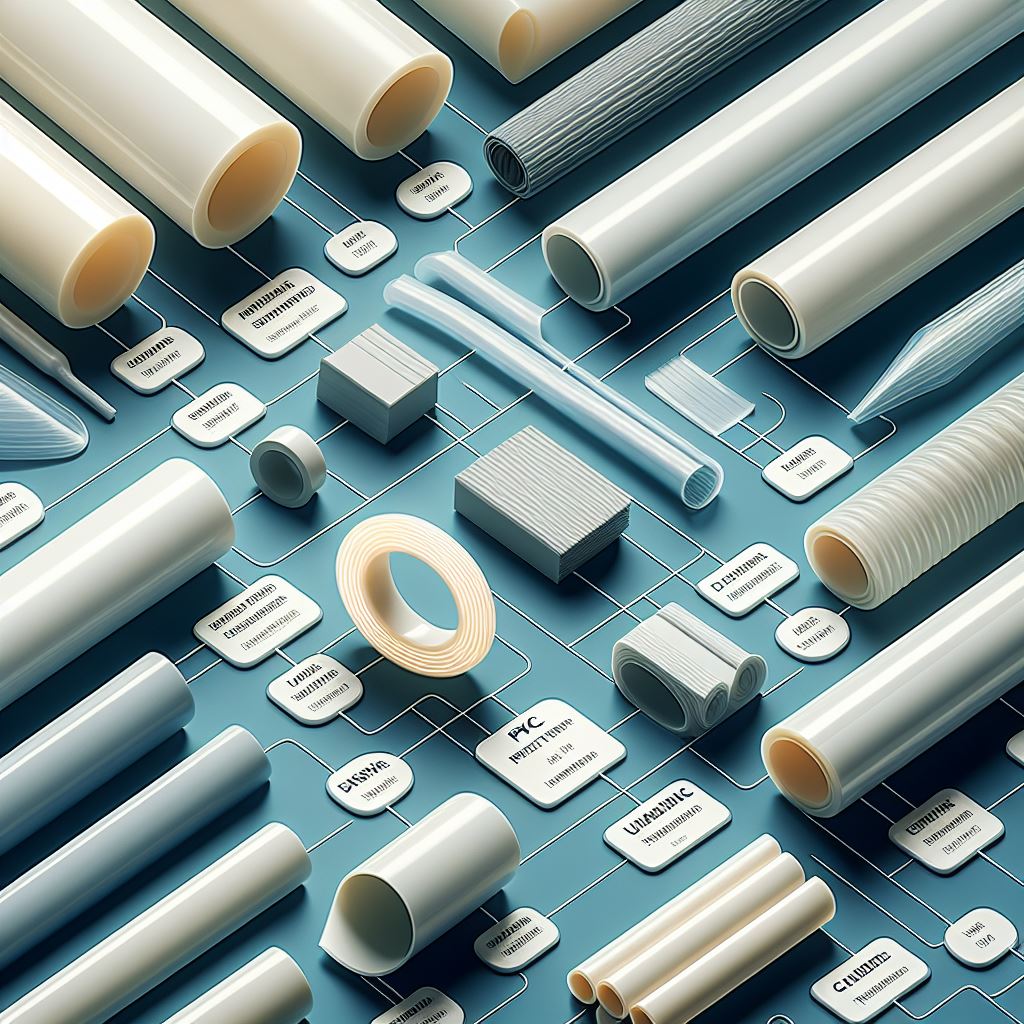

PVC Type Of Plastic: PVC, or polyvinyl chloride, is a common type of plastic that has a wide range of applications in our everyday lives. From pipes and gutters to flooring and even toys, PVC’s versatility makes it a popular choice for both industrial and domestic uses. But with so many different types of PVC available, selecting the right one for your specific needs can be a challenge. This blog post will be your guide to navigating the world of PVC and choosing the perfect type for your next project.

Understanding the Basics of PVC: PVC Type Of Plastic

PVC is a relatively inexpensive and durable plastic known for its rigidity, chemical resistance, and waterproof properties. However, not all PVC is created equal. Manufacturers can modify the base material with various additives and fillers to achieve specific characteristics. These modifications result in two main categories of PVC: rigid PVC (uPVC) and flexible PVC (fPVC).

-

Rigid PVC (uPVC): PVC Type Of Plastic: This is the most common type of PVC. Its strength and dimensional stability make it ideal for applications like pipes, building materials, window frames, and even furniture.

-

Flexible PVC (fPVC): PVC Type Of Plastic: As the name suggests, fPVC is more pliable and can be stretched or bent without breaking. This flexibility makes it suitable for applications like electrical wire insulation, hoses, and inflatable products.

Choosing the Right PVC Type Of Plastic: Key Factors to Consider

Now that you understand the two main categories of PVC, let’s delve into the factors that will help you choose the right type for your project:

-

Application: The primary function of your project is the most crucial factor. Are you building a deck, repairing pipes, or creating a weatherproof sign? Each application has specific requirements for rigidity, flexibility, and other properties.

-

Strength and Durability: Consider the weight and stress the PVC will be subjected to. Rigid PVC is ideal for load-bearing applications, while flexible PVC might be suitable for low-stress uses like electrical insulation.

-

Temperature Resistance: Different PVC formulations have varying temperature tolerances. For applications exposed to extreme heat or cold, choose a PVC specifically designed for those conditions.

-

Chemical Resistance: If your PVC will be in contact with chemicals, like cleaning solutions or certain liquids, ensure it has the appropriate chemical resistance.

-

Flame Retardancy: In some cases, fire safety is a major concern. Specific PVC formulations offer flame-retardant properties, making them suitable for applications near heat sources.

-

UV Resistance: For outdoor applications exposed to sunlight, UV resistance is crucial to prevent the PVC from becoming brittle or cracking over time.

-

Aesthetics: While not always a primary concern, PVC comes in various colors and finishes. Consider the visual impact of the PVC for your project.

Additional Tips for Choosing PVC: PVC Type Of Plastic

- Consult the manufacturer’s specifications: Reputable PVC manufacturers provide detailed information about the properties and intended uses of their products.

- Seek professional guidance: If you’re unsure about the best PVC type for your project, consider consulting a contractor or a professional at your local hardware store.

- Prioritize safety: Always choose PVC that meets relevant safety standards, especially for applications like plumbing or electrical work.

By understanding the different types of PVC and considering these key factors. You can make an informed decision and choose the right PVC for your needs. Remember, PVC offers a vast array of possibilities, and with the right selection, you can ensure a successful and long-lasting project.