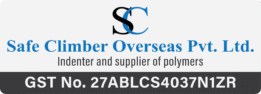

Polypropylene vs Polyvinyl Chloride: When choosing materials for your next project, whether it be plumbing, packaging, or product manufacturing, knowing the difference between polypropylene and polyvinyl chloride can save you thousands of dollars and prevent costly mistakes. These two thermoplastics dominate modern manufacturing, but selecting the wrong one could compromise your product’s performance, safety, and durability. In this comprehensive guide, we will discuss the differences between polypropylene and polyvinyl chloride in detail.

You’ll be able to make decisions that are backed by science and real-world examples thanks to this. Despite the fundamental differences in their composition, properties, and ideal applications, both materials have revolutionized a variety of industries, including healthcare. Polypropylene (PP) has emerged as the preferred material for food containers and automotive components, whereas polyvinyl chloride (PVC) has been the material of choice for rigid pipes and electrical insulation. It’s not just a matter of academics; understanding these distinctions has a direct impact on product performance, environmental sustainability, and your bottom line.

What Are Polypropylene and Polyvinyl Chloride?

Before moving on to the comparison, let’s first talk about the differences between polypropylene and polyvinyl chloride.

Propylene monomers are converted into the thermoplastic polymer polypropylene (PP) via chain-growth polymerization. Since its discovery in the 1950s, polypropylene has evolved into one of the world’s most adaptable plastics. It is light but very strong due to its repeating chemical structure of C3H6 units.

Another polymer that is thermoplastic, Vinyl chloride monomers are used to make polyvinyl chloride (PVC). PVC, which has a chemical formula of (C2H3Cl)n, has chlorine atoms that give it special properties that are both popular and controversial. Since its first polymerization in 1872, PVC has risen to the position of third-most widely produced plastic worldwide. Because of their fundamentally different molecular structures, materials made of polypropylene and polyvinyl chloride perform so differently in different applications.

Comparison 1: Chemical Composition and Structure

Polypropylene Composition

Polypropylene consists entirely of carbon and hydrogen atoms, making it a pure hydrocarbon polymer. This composition gives polypropylene several advantages:

- No halogens: Unlike PVC, PP contains no chlorine or other potentially harmful elements

- Simple structure: The repeating propylene units create a straightforward molecular chain

- Non-toxic nature: Its pure composition makes it ideal for food-contact applications

Polyvinyl Chloride Composition

Polyvinyl chloride contains approximately 57% chlorine by weight, which fundamentally changes its properties:

- Chlorine content: Provides flame resistance but raises environmental concerns

- Requires additives: PVC needs plasticizers, stabilizers, and other additives to function properly

- Complex formulations: Different PVC products can vary significantly based on their additive packages

When comparing polypropylene vs polyvinyl chloride from a chemical standpoint, polypropylene’s simpler composition often translates to easier recycling and fewer health concerns.

Comparison 2: Physical Properties and Durability

Density and Weight

The polypropylene vs polyvinyl chloride density comparison reveals significant differences:

- Polypropylene density: 0.90-0.91 g/cm³ (one of the lightest plastics)

- PVC density: 1.38-1.45 g/cm³ (significantly heavier)

This means polypropylene products weigh about 35-40% less than equivalent PVC items, reducing shipping costs and making handling easier.

Tensile Strength

Both materials offer impressive strength, but their characteristics differ:

Polypropylene:

- Tensile strength: 30-40 MPa

- High impact resistance, especially in copolymer forms

- Excellent fatigue resistance for living hinges

Polyvinyl Chloride:

- Tensile strength: 50-80 MPa (rigid PVC)

- Superior rigidity in unplasticized forms

- Better resistance to deformation under load

Temperature Resistance

Temperature performance is a critical factor in the polypropylene vs polyvinyl chloride debate:

Polypropylene:

- Melting point: 130-171°C (266-340°F)

- Glass transition temperature: -10°C

- Maintains flexibility at low temperatures

Polyvinyl Chloride:

- Melting point: 100-260°C (depending on formulation)

- Glass transition temperature: 87°C

- Becomes brittle at low temperatures without plasticizers

Comparison 3: Manufacturing and Processing

Production Methods

The manufacturing process for polypropylene vs polyvinyl chloride differs substantially:

Polypropylene Production:

- Propylene gas extracted from petroleum refining

- Polymerization using catalysts (typically Ziegler-Natta or metallocene)

- Pelletization for easier handling and shipping

- Processing through injection molding, extrusion, or blow molding

PVC Production:

- Ethylene and chlorine combined to create vinyl chloride monomer

- Polymerization (suspension, emulsion, or bulk methods)

- Addition of stabilizers, plasticizers, and other additives

- Processing through extrusion, calendaring, or molding

Processing Temperatures

When manufacturers choose between polypropylene vs polyvinyl chloride, processing temperature is crucial:

- PP processing: Requires 200-280°C, demanding more energy

- PVC processing: Operates at 160-210°C, more energy-efficient

- Equipment wear: PP’s higher temperatures can increase machinery maintenance costs

Comparison 4: Chemical Resistance

Polypropylene Chemical Resistance

Polypropylene excels in resisting various chemicals:

- Acids and bases: Excellent resistance to most acids and alkalis at room temperature

- Organic solvents: Vulnerable to aromatic hydrocarbons and chlorinated solvents at high temperatures

- Water absorption: Virtually none (0.01-0.03%), making it ideal for wet environments

PVC Chemical Resistance

When comparing polypropylene vs polyvinyl chloride for chemical resistance, PVC shows:

- Acids: Excellent resistance to mineral acids, alkalis, and salts

- Oils and hydrocarbons: Good resistance to petroleum products

- Alcohols: Generally resistant, though plasticizers may migrate

- Solvents: Poor resistance to ketones, chlorinated hydrocarbons, and aromatics

For chemical storage and transport, the polypropylene vs polyvinyl chloride choice depends heavily on the specific chemicals involved.

Comparison 5: Environmental Impact and Sustainability

Recyclability

The environmental footprint of polypropylene vs polyvinyl chloride is a growing concern:

Polypropylene Recycling:

- Recycling code: #5

- Relatively easy to recycle

- Can be reprocessed multiple times with minimal degradation

- Growing infrastructure for PP recycling worldwide

PVC Recycling:

- Recycling code: #3

- More challenging to recycle due to additives

- Chlorine content complicates the recycling process

- Limited recycling facilities accept PVC

Production Environmental Impact

Polypropylene:

- Lower greenhouse gas emissions during production

- No toxic chlorine byproducts

- Fossil fuel-derived but cleaner production process

PVC:

- Higher environmental impact from chlorine production

- Potential dioxin release if improperly incinerated

- Additive leaching concerns in landfills

The polypropylene vs polyvinyl chloride environmental comparison increasingly favors polypropylene as sustainability becomes more important.

Comparison 6: Cost Considerations

Raw Material Costs

Price is always a factor when choosing between polypropylene vs polyvinyl chloride:

- Polypropylene: Generally $1.00-$1.50 per pound (varies with oil prices)

- PVC: Typically $0.60-$1.00 per pound

- Price volatility: Both fluctuate with petroleum markets, but PVC also depends on chlorine costs

Total Cost of Ownership

Beyond raw material costs, consider:

Polypropylene:

- Lower shipping costs due to lighter weight

- Potentially longer service life in certain applications

- Less maintenance in chemical environments

PVC:

- Lower initial material cost

- May require more frequent replacement in UV exposure

- Potential costs for special disposal or recycling

Comparison 7: Applications and Use Cases

Where Polypropylene Excels

Polypropylene dominates in applications where its unique properties shine:

Packaging:

- Food containers (microwave-safe)

- Bottle caps and closures

- Flexible packaging films

- Yogurt containers and similar products

Automotive:

- Interior trim components

- Battery cases

- Bumpers and body panels

- Under-the-hood applications

Medical:

- Syringes and medical vials

- Specimen containers

- Surgical instruments

- Disposable labware

Textiles:

- Carpeting and rugs

- Reusable shopping bags

- Rope and cordage

- Geotextiles

Where PVC Excels

When comparing polypropylene vs polyvinyl chloride, PVC is preferred for:

Construction:

- Water and sewer pipes

- Window frames and profiles

- Siding and cladding

- Roofing membranes

Electrical:

- Wire and cable insulation

- Electrical conduit

- Junction boxes

- Cable jacketing

Medical:

- IV bags and tubing (flexible PVC)

- Blood bags

- Dialysis equipment

- Breathing tubes

Flooring:

- Vinyl tiles and sheets

- Luxury vinyl planks

- Commercial flooring systems

- Anti-static flooring

Comparison 8: Safety and Health Considerations

Polypropylene Safety Profile

Polypropylene is generally considered one of the safest plastics:

- FDA approved: Widely used for food contact applications

- No BPA or phthalates: Pure PP contains no endocrine disruptors

- Inert nature: Minimal chemical leaching under normal use

- Burn characteristics: Burns cleanly without releasing toxic chlorine gases

PVC Safety Concerns

The polypropylene vs polyvinyl chloride safety comparison is more complex for PVC:

Potential concerns:

- Plasticizers: Phthalates in flexible PVC raise health questions

- Stabilizers: Lead and cadmium historically used (now restricted)

- Vinyl chloride monomer: Carcinogenic if exposure occurs during production

- Combustion products: Releases hydrochloric acid and dioxins when burned

Important note: Modern PVC formulations have addressed many historical concerns, especially in regulated industries like medical and food packaging.

Comparison 9: Weather and UV Resistance

Outdoor Performance

For outdoor applications, the polypropylene vs polyvinyl chloride comparison reveals:

Polypropylene:

- UV resistance: Poor without additives; requires UV stabilizers

- Weathering: Degrades and becomes brittle with prolonged sun exposure

- Solutions: Carbon black or UV stabilizers significantly improve performance

- Best use: Indoor applications or UV-protected outdoor uses

Polyvinyl Chloride:

- UV resistance: Better natural resistance, but still requires additives

- Weathering: Maintains properties longer in outdoor environments

- Color stability: Can chalk or discolor but maintains structural integrity

- Best use: Excellent for long-term outdoor applications

Comparison 10: Flexibility and Rigidity Options

Polypropylene Flexibility

Polypropylene offers a range of rigidity through different forms:

- Homopolymer PP: Rigid, high tensile strength

- Copolymer PP: More flexible, better impact resistance

- Living hinges: Unique ability to create integral flexible hinges

- TPO blends: Combining with rubber for automotive applications

PVC Flexibility

The polypropylene vs polyvinyl chloride flexibility comparison shows PVC’s versatility:

- Rigid PVC (uPVC): Very stiff, used for pipes and construction

- Flexible PVC: Achieved through plasticizers, extremely pliable

- Range: From hard pipe to soft tubing with the same base polymer

- Customization: Easily adjusted through additive formulations

Comparison 11: Thermal Expansion and Dimensional Stability

Coefficient of Thermal Expansion

Understanding how materials expand with heat is crucial in the polypropylene vs polyvinyl chloride selection:

Polypropylene:

- Coefficient: 80-100 × 10⁻⁶ /°C

- Higher expansion than PVC

- Requires expansion joints in longer runs

- Can warp if unevenly heated

PVC:

- Coefficient: 50-100 × 10⁻⁶ /°C (varies with formulation)

- Better dimensional stability

- Less movement in temperature fluctuations

- Preferred for applications requiring tight tolerances

Moisture Absorption

Both materials resist water, but differently:

- Polypropylene: Absorbs virtually no moisture (0.01-0.03%)

- PVC: Minimal absorption (0.04-0.4%), slightly higher than PP

- Practical impact: Both excellent for wet environments, minimal swelling

Comparison 12: Electrical Properties

Insulation Capabilities

For electrical applications, comparing polypropylene vs polyvinyl chloride reveals:

Polypropylene:

- Dielectric constant: 2.2-2.3 (excellent)

- Volume resistivity: Very high (>10¹⁶ ohm-cm)

- Dielectric strength: 20-30 kV/mm

- Applications: Capacitors, cable insulation for high-frequency applications

PVC:

- Dielectric constant: 3.0-4.0

- Volume resistivity: High (10¹⁴-10¹⁵ ohm-cm)

- Dielectric strength: 15-40 kV/mm

- Applications: Standard wire and cable insulation, electrical boxes

Flame Resistance

Fire safety is a critical factor in the polypropylene vs polyvinyl chloride decision:

Polypropylene:

- Naturally flammable (burns easily)

- Requires flame retardant additives for fire-rated applications

- Burns with relatively clean smoke

- Limited oxygen index: 17-18%

PVC:

- Self-extinguishing due to chlorine content

- Limited oxygen index: 45-49%

- Produces toxic smoke when burning

- Often chosen for fire safety-critical applications

Choosing Between Polypropylene vs Polyvinyl Chloride: Decision Matrix

To help you decide between polypropylene vs polyvinyl chloride, consider these key questions:

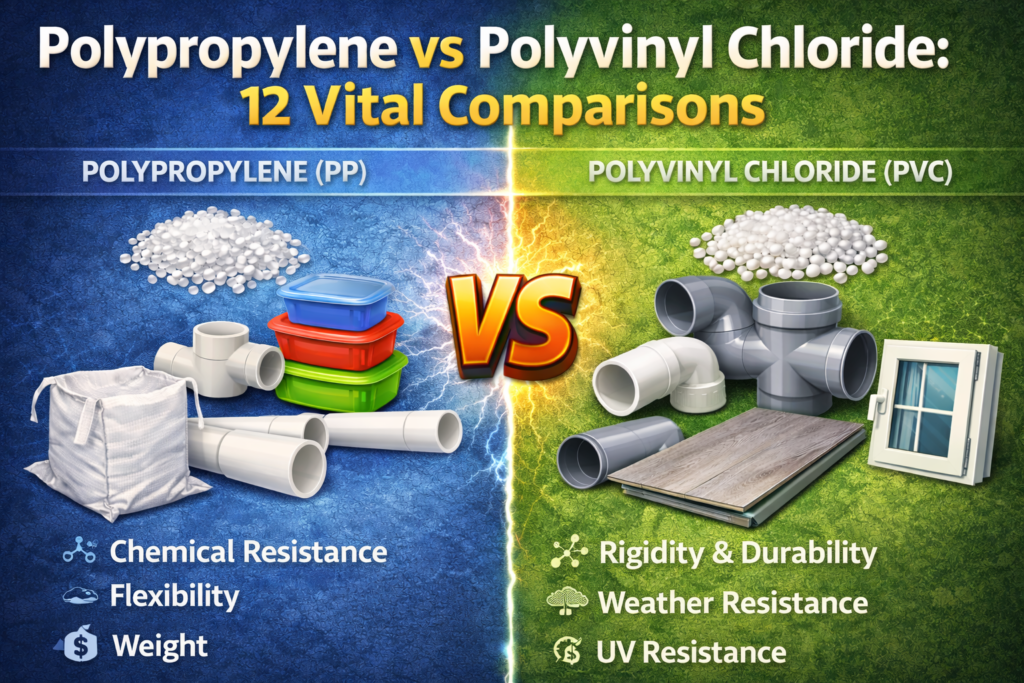

Choose Polypropylene when:

- Food contact or medical safety is paramount

- Lightweight is crucial for shipping or handling

- Chemical resistance to acids and bases is needed

- Environmental sustainability is a priority

- Flexibility and fatigue resistance are required

- You need microwave-safe containers

Choose PVC when:

- Cost is the primary driver

- Fire resistance is essential

- Long-term outdoor exposure without UV protection

- Rigid structural applications (pipes, window frames)

- Electrical insulation for standard applications

- Weatherability is more important than recyclability

Industry-Specific Recommendations

Construction Industry

In construction, the polypropylene vs polyvinyl chloride choice often favors PVC for:

- Plumbing systems (superior rigidity and chemical resistance)

- Window frames (better weather resistance)

- Electrical conduit (flame resistance)

However, polypropylene works better for:

- Drainage systems requiring flexibility

- Chemical-resistant drainage in laboratories

- Lightweight roofing components

Packaging Industry

For packaging, polypropylene vs polyvinyl chloride comparisons typically favor polypropylene:

- Food containers (FDA compliance and safety)

- Microwaveable packaging (heat resistance)

- Bottle caps (excellent fatigue resistance)

PVC is still used for:

- Blister packaging (excellent clarity and stiffness)

- Clamshell containers (rigid, clear, cost-effective)

Automotive Industry

The automotive sector increasingly prefers polypropylene:

- Lighter weight improves fuel efficiency

- Better impact resistance for interior components

- Easier recyclability supports sustainability goals

PVC remains important for:

- Wire harness insulation

- Underbody coatings

- Some interior trim applications

Frequently Asked Questions

1. Which is safer for food contact: polypropylene vs polyvinyl chloride?

In general, polypropylene is regarded as safer for food contact. It has been approved by the FDA for direct food contact and does not contain chlorine, phthalates, or BPA. Despite the fact that some formulations of PVC are also approved by the FDA, polypropylene is the preferred material for food containers, particularly those heated in microwaves, due to its simpler composition.

2. Can both polypropylene and polyvinyl chloride be recycled?

Although polypropylene (number 5) is generally easier to recycle than PVC (number 3), both materials can be recycled. Polypropylene can be reprocessed with less degradation and has improved recycling infrastructure. Due to its chlorine content and additives, PVC recycling is more difficult, and fewer facilities accept it.

3. Which material lasts longer outdoors: polypropylene vs polyvinyl chloride?

Outdoor applications typically have a longer lifespan for PVC. Polypropylene is inferior in terms of weatherability and natural resistance to UV light. PVC is ideal for siding, window frames, and outdoor piping because it maintains its properties better over prolonged outdoor exposure than polypropylene, which can be UV-stabilized.

4. What’s the cost difference between polypropylene vs polyvinyl chloride?

As a raw material, PVC typically costs 30 to 40 percent less per pound. However, the lower shipping costs associated with polypropylene can offset this cost advantage due to its lighter weight. The final cost is influenced by processing, durability, and disposal costs, which all depend on the application.

5. Which material is better for plumbing: polypropylene vs polyvinyl chloride?

PVC is the traditional choice for plumbing due to its superior rigidity, lower cost, and excellent chemical resistance to common drain chemicals. Polypropylene, on the other hand, is gaining popularity for drainage systems that need to be flexible and for applications involving acidic or basic chemicals, where it excels in chemical resistance.

6. Are there health concerns with polypropylene vs polyvinyl chloride?

Due to its straightforward composition, polypropylene poses few health risks. PVC’s production-related use of phthalate plasticizers and vinyl chloride monomers has raised additional health concerns. However, modern regulated PVC products, especially in medical and food applications, meet strict safety standards. The risk depends on the specific formulation and application.

7. Which material is more environmentally friendly?

Polypropylene is generally considered more environmentally friendly. It is simpler to recycle, produces fewer toxic byproducts during manufacturing, and does not emit chlorine compounds when disposed of. Despite the fact that proper recycling and disposal mitigate these issues, the chlorine content of PVC and the potential for dioxin release during incineration raise environmental concerns.

8. Can polypropylene and PVC be used together in products?

PVC and polypropylene can be used in different parts of the same product, but they can’t be easily bonded together without using special adhesives or mechanical fasteners. Their distinct chemical properties prevent straightforward fusion. Each material should be used where its specific properties provide the most benefit.

9. Which material is better for high-temperature applications?

Polypropylene is superior to standard PVC in its ability to withstand continuous temperatures of up to 100°C (212°F). Containers made of polypropylene can even be safely microwaved. If it is not specially formulated, PVC begins to soften and deform at lower temperatures. Polypropylene is typically the better option for applications that require heat resistance.

10. What are the main disadvantages of each material?

Without additives, polypropylene has poor UV resistance, requires higher processing temperatures, and is flammable. Environmental concerns about chlorine content, more complicated recycling, the possibility of plasticizer migration, and toxic smoke from burning PVC are among its drawbacks. When choosing between polypropylene and polyvinyl chloride, it’s important to know these limitations.

Conclusion: Making the Right Choice

There is no one-size-fits-all answer to the polypropylene vs. polyvinyl chloride debate. Due to distinct advantages that make them irreplaceable in certain applications, both materials have established a place in modern manufacturing.

When it comes to weight, recyclability, and safety, polypropylene wins hands down. Its superior performance in these challenging applications is reflected in its dominance in food packaging, medical devices, and automotive components. Polypropylene has a significant advantage for businesses that are committed to reducing their environmental footprint because of its simpler recyclability and cleaner environmental profile as sustainability becomes increasingly important.

For applications requiring rigidity, fire resistance, and outdoor weatherability at a competitive price point, polyvinyl chloride remains unrivaled. PVC’s unique value proposition can be seen in the industry’s continued use for electrical, plumbing, and window frame applications. Modern PVC formulations and proper handling address numerous historical issues, despite environmental concerns.

Key Takeaways from Polypropylene vs Polyvinyl Chloride Comparison

When making your decision between polypropylene vs polyvinyl chloride, remember:

- Safety first: For food contact and medical applications, polypropylene’s safety profile is superior

- Consider the environment: Both location and sustainability matter; choose based on actual exposure conditions

- Calculate total cost: Look beyond material prices to shipping, processing, and lifecycle costs

- Match properties to needs: Don’t over-engineer; use the material that meets your minimum requirements

- Think long-term: Consider maintenance, replacement cycles, and end-of-life disposal

The comparison of polypropylene vs polyvinyl chloride ultimately comes down to matching material properties with your specific application requirements. You are now equipped to make informed decisions that optimize performance, safety, cost, and impact on the environment by comprehending the twelve essential comparisons we have looked at, from electrical properties to chemical composition.

Better decisions can be made when you know the differences between polypropylene and polyvinyl chloride, whether you’re designing a new product, choosing construction materials, or just trying to figure out which plastic is in your everyday items. As material science advances, both polymers continue evolving with improved formulations, recycling technologies, and sustainable alternatives on the horizon.

Now is the time to take action: Consider whether polypropylene or polyvinyl chloride is being utilized appropriately in your current applications. Sometimes a simple material switch can dramatically improve product performance, reduce costs, or enhance your environmental credentials.