The creation of polyvinyl chloride (PVC) is one of the most fascinating and extensively used processes in the vast and complex world of industrial manufacturing. Whether you work in packaging, construction, or even medicine, PVC is a substance you have probably come across. However, how is this multipurpose plastic produced? We will examine the PVC manufacturing process flow diagram in detail in this extensive guide, revealing the top 5 secrets that contribute to this process’s effectiveness, sustainability, and innovation. You will have a thorough understanding of PVC production, the importance of the flow diagram, and the trade secrets that contribute to its success at the end of this article.

What is a PVC Manufacturing Process Flow Diagram?

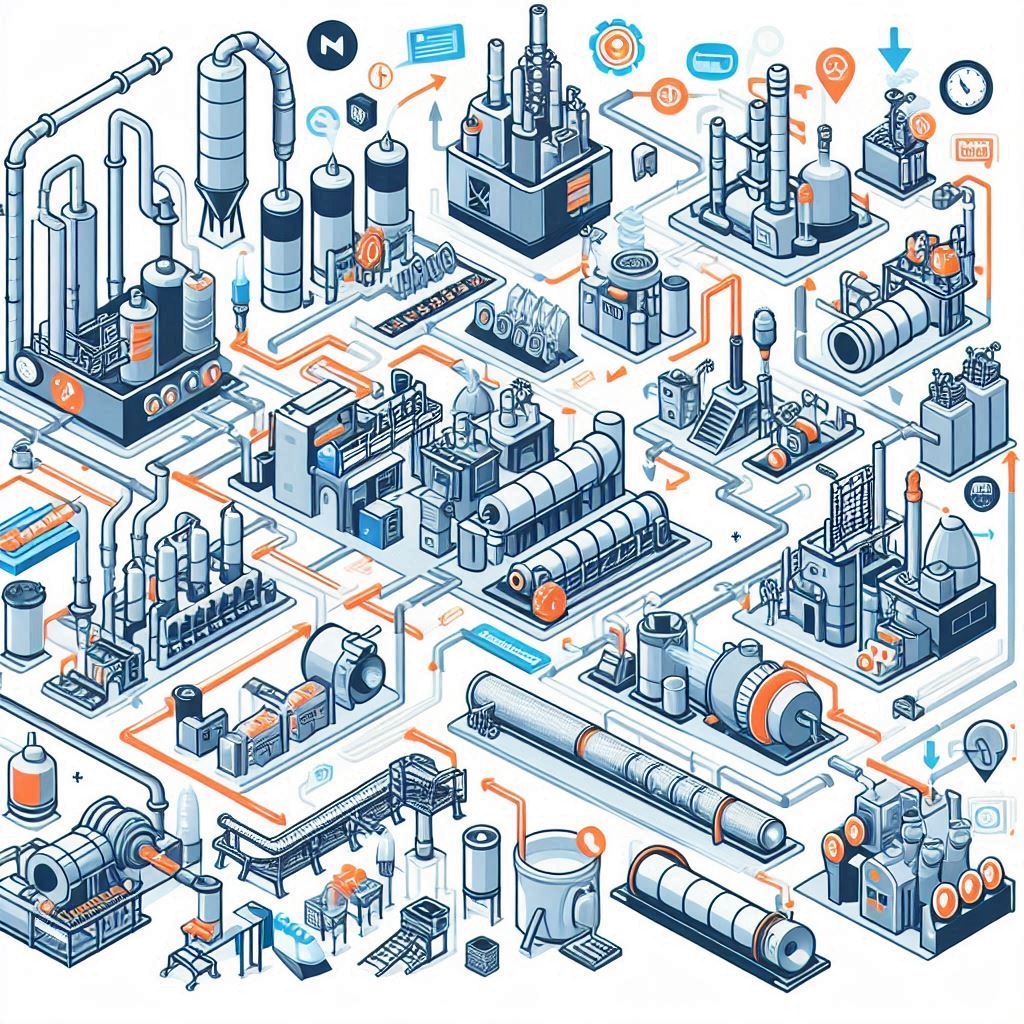

Before we soar into the secrets and techniques, let’s set up what a PVC production procedure glide diagram is. A glide diagram is a visible illustration of the sequential steps concerned in reworking uncooked substances into completed PVC products. It maps out the adventure from the extraction of uncooked substances to the very last polymerization and compounding degrees. This diagram is a vital device for producers, engineers, and exceptional manipulate teams, because it guarantees each level is optimized for performance and safety.

The PVC production procedure glide diagram normally consists of degrees like uncooked fabric preparation, polymerization, compounding, and extrusion or molding. Each step is interconnected, and knowledge the glide enables producers discover bottlenecks, enhance productivity, and keep regular exceptional. Now, let’s discover the pinnacle five secrets and techniques that make this procedure stand out.

Secret 1: The Magic of Raw Material Selection

The first secret in the PVC manufacturing process flow diagram lies in the selection of raw materials. PVC is primarily made from two key ingredients: ethylene (derived from petroleum or natural gas) and chlorine (sourced from salt via electrolysis). The magic happens when these raw materials are combined to form vinyl chloride monomer (VCM), the building block of PVC.

Why It’s a Secret

The nice of uncooked substances without delay affects the very last product. Manufacturers frequently preserve their sourcing techniques below wraps due to the fact the purity of ethylene and chlorine can range significantly. For instance, the use of high-purity chlorine reduces impurities withinside the very last PVC, making it extra long lasting and appropriate for programs like scientific tubing or water pipes.

Key Points:

Ethylene Purity: Must be at least 99.9% to ensure efficient reaction.

Chlorine Sourcing: Electrolysis of salt (NaCl) produces chlorine gas, which must be free of contaminants.

Sustainability Factor: Some manufacturers are now using bio-based ethylene to reduce their carbon footprint.

In the PVC manufacturing process flow diagram, this stage is often the first box, labeled “Raw Material Preparation.” It’s where the foundation for high-quality PVC is laid.

Secret 2: The Precision of Polymerization

The second secret in the PVC manufacturing process flow diagram is the polymerization process, where vinyl chloride monomer (VCM) is transformed into polyvinyl chloride (PVC). This step is the heart of the process, and its precision is what sets top manufacturers apart.

How Polymerization Works

Polymerization happens in big reactors beneathneath managed situations of temperature, pressure, and catalysts. The VCM molecules hyperlink collectively to shape lengthy chains, developing the PVC polymer. There are 3 predominant forms of polymerization utilized in PVC production: suspension, emulsion, and bulk polymerization. Suspension polymerization is the maximum common, accounting for over 80% of worldwide PVC production.

Why It’s a Secret

The exact conditions—like temperature (typically 50–70°C) and pressure (around 5–10 bar)—are closely guarded trade secrets. Even a slight variation can affect the molecular weight of the PVC, which determines its strength, flexibility, and suitability for specific applications.

Key Points:

Temperature Control: Precise heating ensures uniform polymerization.

Catalyst Efficiency: Specialized catalysts speed up the reaction without compromising quality.

Safety Measures: VCM is flammable and toxic, so reactors are equipped with advanced safety systems.

In the PVC manufacturing process flow diagram, this stage is depicted as a central hub, with inputs (VCM, catalysts) and outputs (PVC slurry) marked.

Secret 3: The Art of Additives in Compounding

The third secret in the PVC manufacturing process flow diagram is the compounding stage, where raw PVC is mixed with additives to enhance its properties. This step is often overlooked, but it’s where PVC transforms from a basic polymer into a versatile material tailored for specific uses.

What Happens During Compounding?

After polymerization, the PVC is in a powder or slurry form. During compounding, it’s blended with additives like plasticizers (for flexibility), stabilizers (for heat resistance), and pigments (for color). The mixture is then heated and kneaded in a high-speed mixer to create a uniform compound.

Why It’s a Secret

The exact formulation of additives is a closely guarded secret because it determines the final properties of the PVC. For example, a manufacturer producing PVC for window frames might use a different stabilizer than one making PVC for flexible hoses. These formulations are often the result of years of research and development.

Table: Common Additives in PVC Compounding

| | | |

|---|

| | | |

| Prevent degradation during heat | | |

| | | |

| | | |

| | | |

Key Points:

Customization: Additives are tailored to the end product’s requirements.

Innovation: New eco-friendly stabilizers are replacing lead-based ones.

Quality Control: Uniform mixing ensures consistent product performance.

In the PVC manufacturing process flow diagram, compounding is shown as a critical step before the final shaping of the PVC.

Secret 4: Energy Efficiency in Extrusion and Molding

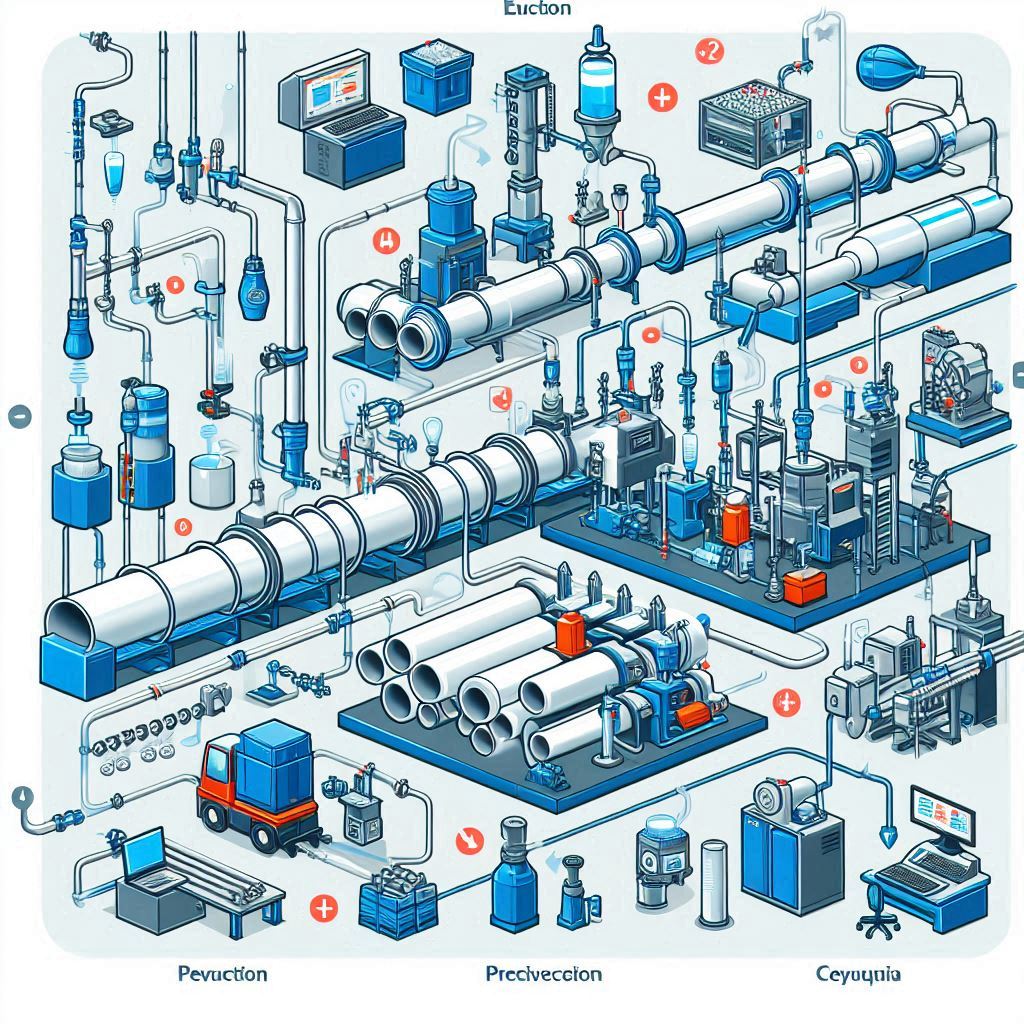

The fourth secret in the PVC manufacturing process flow diagram is the energy efficiency achieved during the extrusion and molding stages. These are the final steps where the compounded PVC is shaped into pipes, sheets, or other products.

How Extrusion and Molding Work

In extrusion, the PVC compound is heated and forced through a die to create continuous shapes like pipes or profiles. In molding, the compound is injected into molds to form specific shapes, such as fittings or containers. Both processes require precise control of temperature and pressure to avoid defects.

Why It’s a Secret

Top manufacturers have developed proprietary techniques to reduce energy consumption during these stages. For example, some use advanced cooling systems to speed up the process, while others recycle waste heat to preheat the PVC compound. These innovations can reduce energy usage by up to 30%, giving companies a competitive edge.

Key Points:

Energy Savings: Modern extruders use 25% less energy than older models.

Automation: Computer-controlled systems ensure precision and reduce waste.

Sustainability: Recycled PVC is increasingly used in extrusion to lower costs.

In the PVC manufacturing process flow diagram, extrusion and molding are the final stages, often depicted with arrows leading to the finished product.

Secret 5: The Role of Quality Control and Testing

The fifth and final secret in the PVC manufacturing process flow diagram is the rigorous quality control and testing that happens at every stage. This ensures that the final PVC product meets industry standards and customer expectations.

What Quality Control Involves

Quality control starts with testing raw materials for purity, continues through polymerization to check molecular weight, and ends with final product testing for strength, flexibility, and durability. Advanced technologies like spectroscopy and tensile testing are used to evaluate the PVC at each stage.

Why It’s a Secret

The specific testing methods and standards are often proprietary. For example, a manufacturer might use a unique combination of tests to ensure their PVC pipes can withstand high pressure, giving them an edge in the market. Additionally, some companies invest in AI-driven quality control systems that predict defects before they occur, a technique they’re unlikely to share with competitors.

Key Points:

Testing Frequency: At least 10 tests are conducted throughout the process.

Standards Compliance: PVC must meet standards like ASTM D1785 for pipes.

Innovation: AI is being used to improve defect detection by 40%.

In the PVC manufacturing process flow diagram, quality control is often represented as a feedback loop, with checkpoints at each major stage.

Why the PVC Manufacturing Process Flow Diagram Matters

The PVC production method waft diagram is greater than only a technical drawing—it is a roadmap to efficiency, exceptional, and innovation. By know-how the waft, producers can optimize every step, lessen waste, and bring brilliant PVC merchandise that meet the desires of diverse industries. The secrets and techniques we have got unveiled—uncooked cloth selection, polymerization precision, additive compounding, electricity efficiency, and exceptional control—spotlight the complexity and ingenuity in the back of PVC production.

Benefits of Understanding the Flow Diagram:

Improved Efficiency: Identifying bottlenecks saves time and resources.

Enhanced Quality: Consistent processes lead to reliable products.

Sustainability: Optimized steps reduce energy use and waste.

Innovation: Understanding the flow inspires new techniques and improvements.

Cost Savings: Streamlined processes lower production costs by up to 15%.

FAQ

1. What is the first step in the PVC manufacturing process flow diagram?

The first step is raw material preparation, where ethylene and chlorine are sourced and processed to create vinyl chloride monomer (VCM). This sets the foundation for the entire process.

2. Why is polymerization critical in the PVC manufacturing process flow diagram?

Polymerization transforms VCM into PVC by linking monomers into long polymer chains. It’s critical because the conditions during this stage determine the PVC’s strength, flexibility, and overall quality.

3. What additives are used in the PVC manufacturing process flow diagram?

Additives like plasticizers, stabilizers, pigments, lubricants, and fillers are used during the compounding stage to enhance PVC’s properties, such as flexibility, heat resistance, and color.

4. How does the PVC manufacturing process flow diagram promote sustainability?

The flow diagram helps manufacturers identify areas for improvement, such as using bio-based raw materials, recycling waste heat, and incorporating recycled PVC, all of which reduce environmental impact.

5. What role does quality control play in the PVC manufacturing process flow diagram?

Quality control ensures that the PVC meets industry standards at every stage, from raw material testing to final product evaluation. It prevents defects and ensures reliability.

6. Can the PVC manufacturing process flow diagram be used for other plastics?

While the general structure of a flow diagram can be applied to other plastics, the specific steps for PVC—like VCM polymerization—are unique. However, the principles of efficiency and quality control are universal.

Conclusion

The PVC production procedure float diagram is a effective device that unveils the intricacies of PVC production. By exploring the pinnacle five secrets—uncooked fabric selection, polymerization precision, additive compounding, power efficiency, and first-rate control—we have got shed mild at the innovation and information in the back of this crucial fabric. Whether you are a producer trying to optimize your procedure or a curious reader trying to recognize how regular merchandise are made, the PVC production procedure float diagram gives a wealth of insights.

From the careful selection of raw materials to the final quality checks, every step in the PVC manufacturing process flow diagram is designed to ensure efficiency, sustainability, and quality. As the industry continues to evolve, these secrets will pave the way for even more advancements in PVC production, making it an exciting space to watch. So, the next time you use a PVC pipe, window frame, or medical device, you’ll know the fascinating journey it took to get to you—thanks to the PVC manufacturing process flow diagram and the secrets behind it.